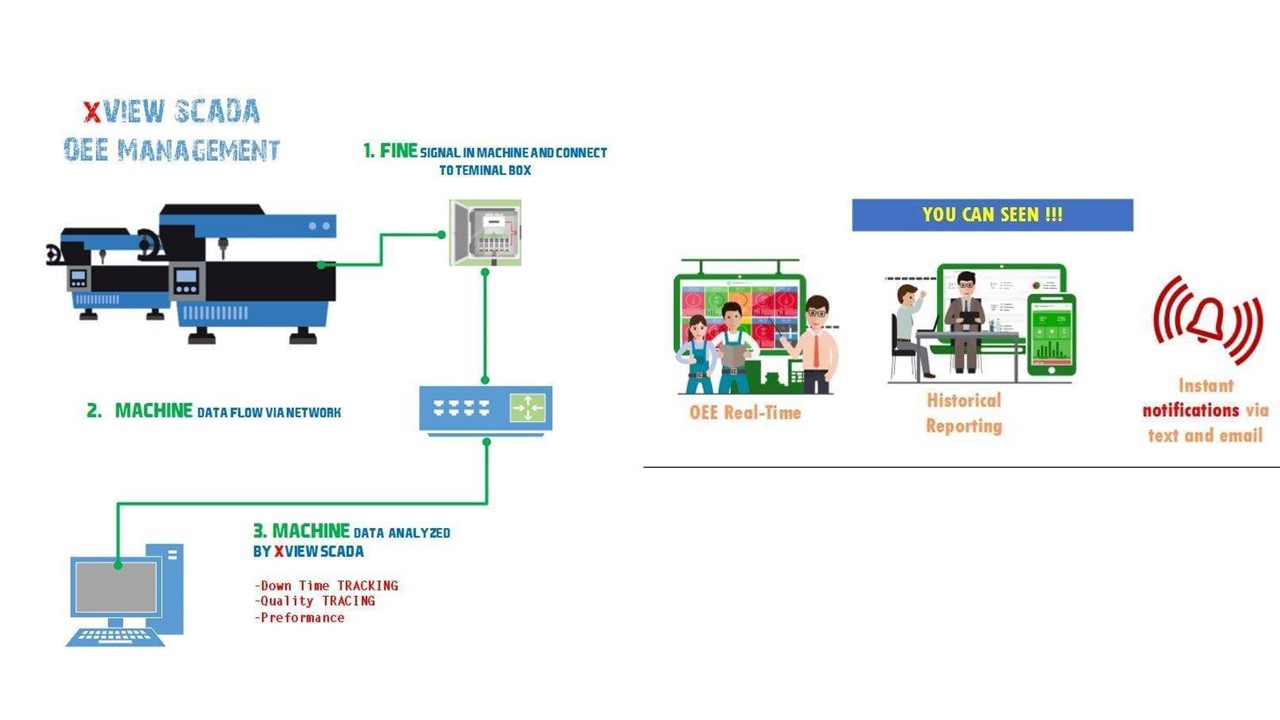

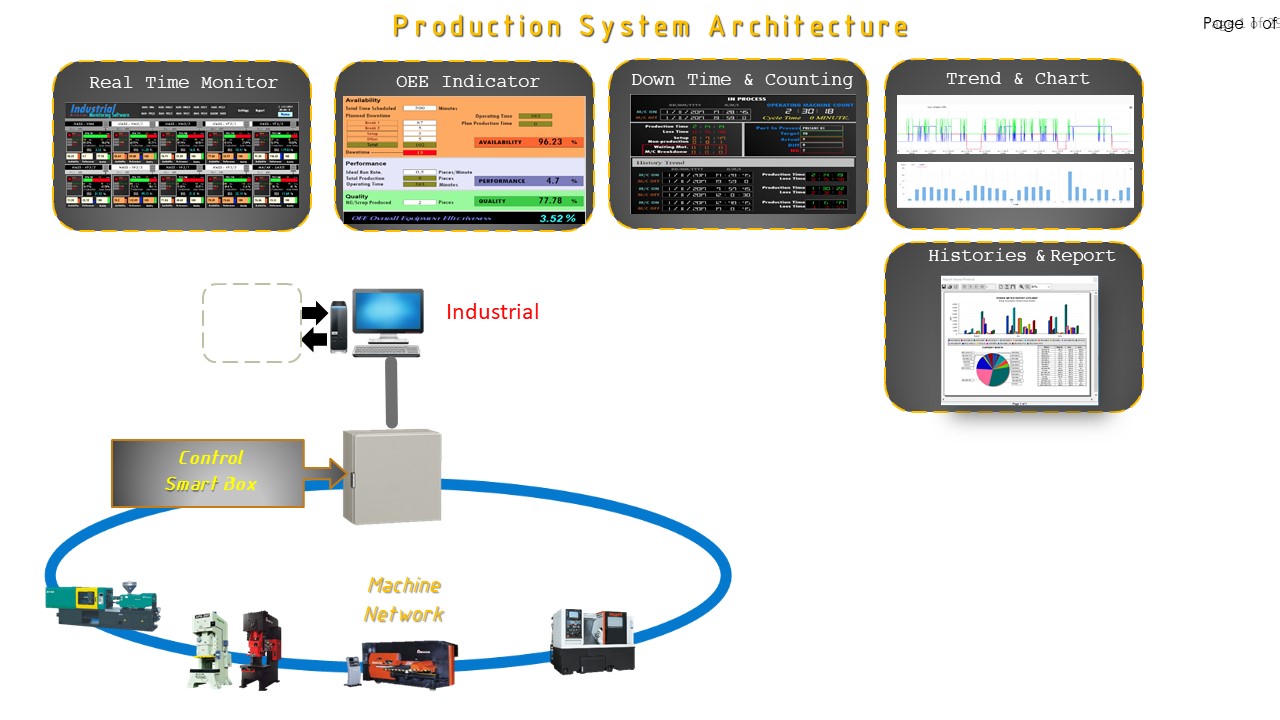

OEE monitoring & real time management software

Features

•Automatic / manual data collection

Machine events can be collected automatically or sent manually by machine operators

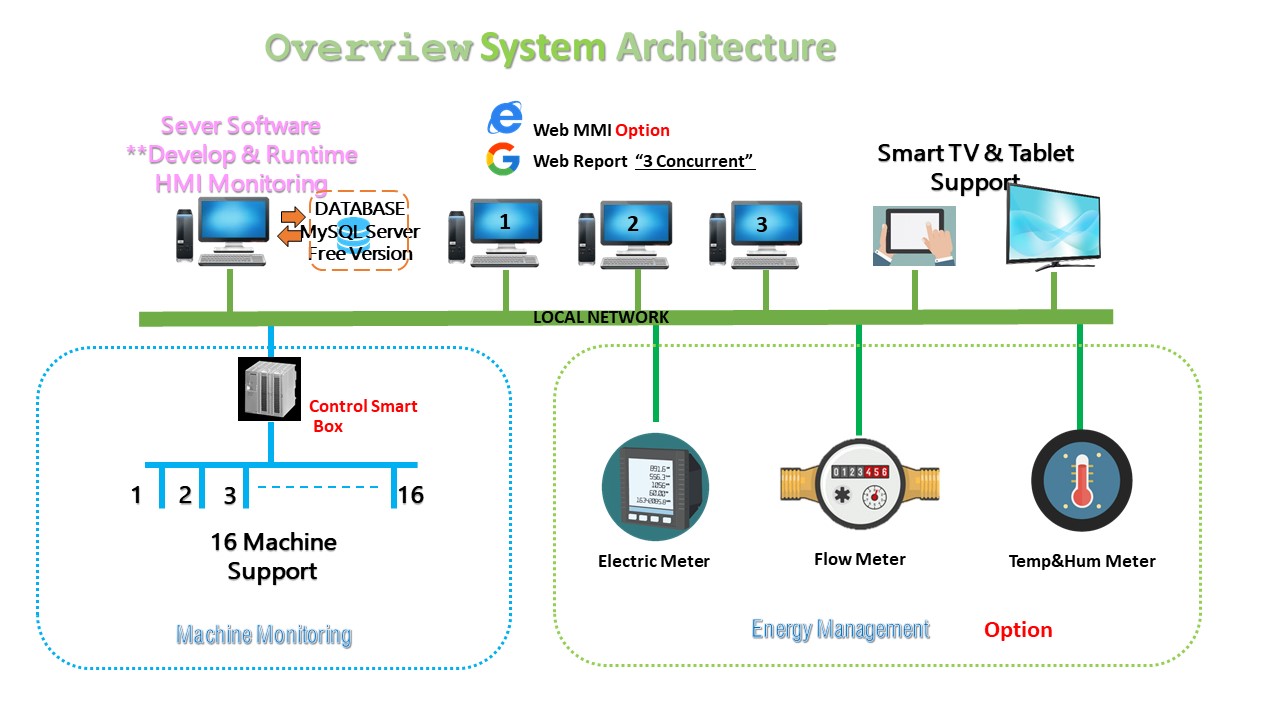

•Use existing network to monitor CNC machines, robots, PLCs

Supports Wireless, Ethernet, RS-232 and Parallel I/O

•Real-time monitoring

Supports multiple “Live Screens” for displaying machine status on large TV screens, Web client and PC

•Customizable Reports and Charts

Add production targets, work shifts or calculate KPIs such as OEE,

•Web Client for tablets and smartphones

See status of your machines or send operator events from any modern mobile device

•Multiple plant support

Monitor multiple plants and access from anywhere

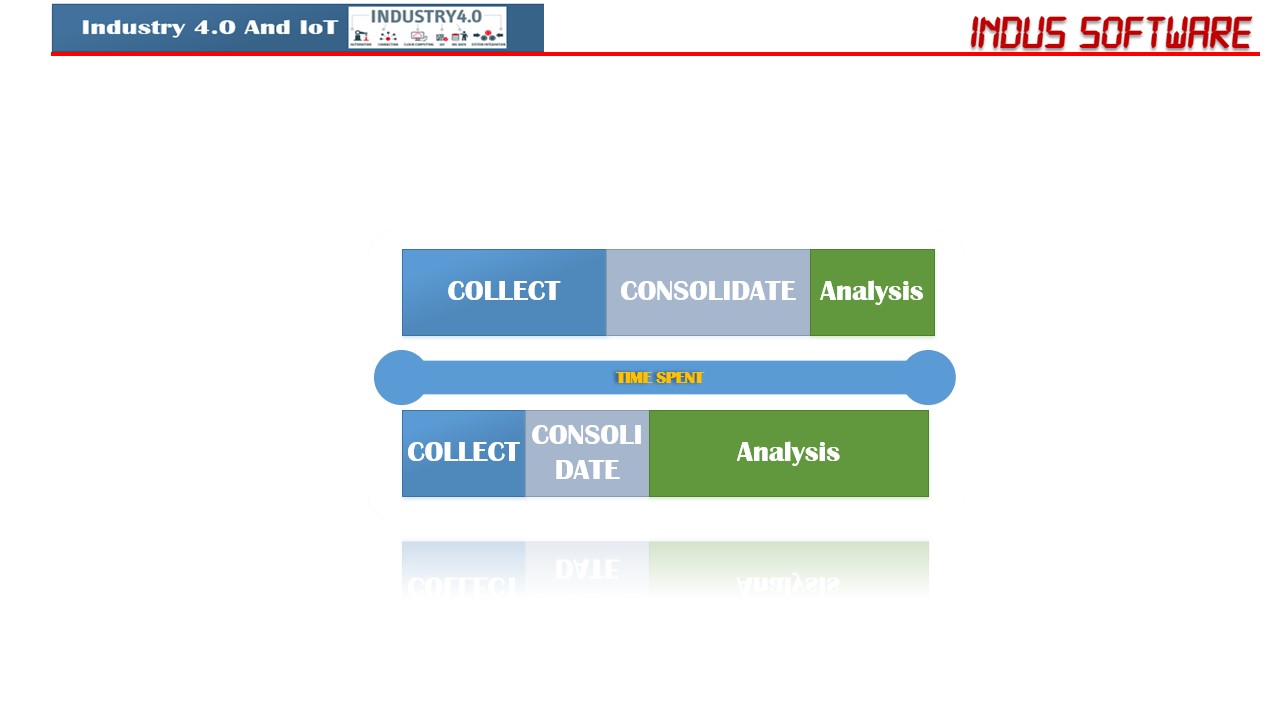

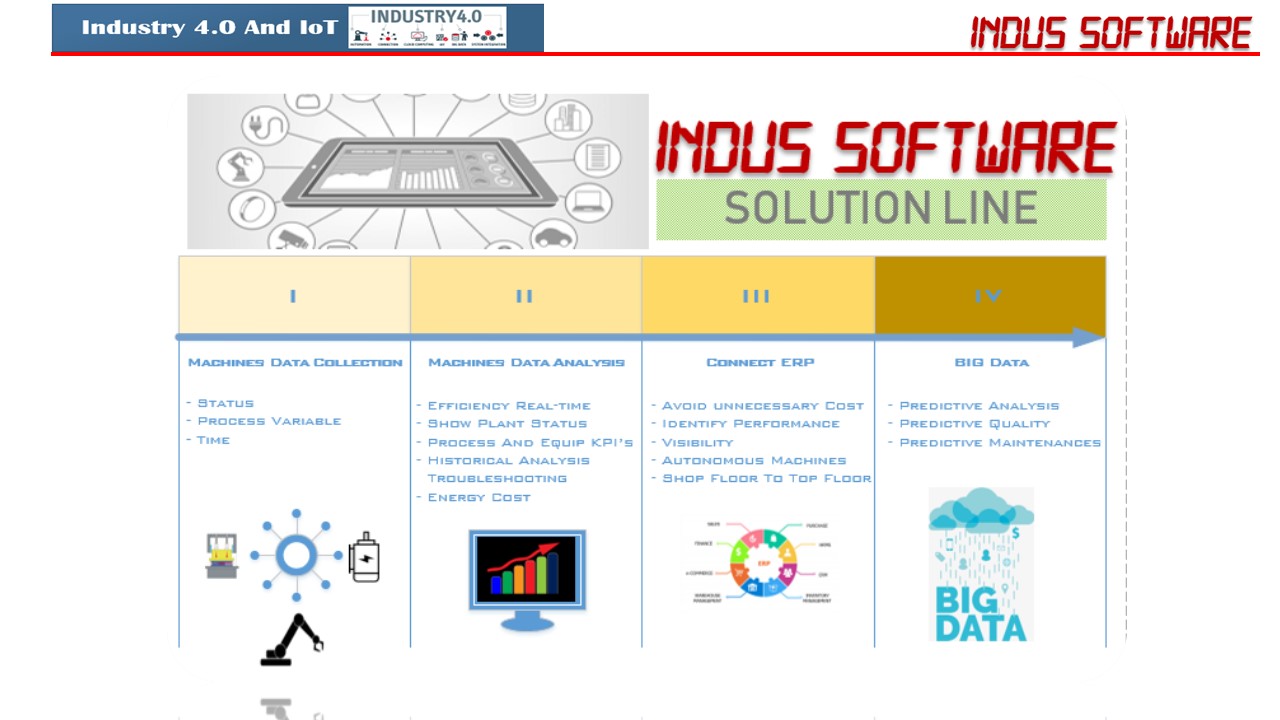

Real-timestatusupdates

Show plantstatus, process variables, production and equipment KPI’s and can be compared with historical data for trend analysis and troubleshooting.

ControlledAlert Management

Define parameters for alerts or alarms to provide an early warning system for abnormal or unplan edevents – reducing accidents.

PreventativeMaintenance & Monitoring

Identify performance issues before they occur, avoiding costly down-time.

Ensure operations are performing at optimal levels.

BENEFITS

- Increase efficiency of operations and production.

- Reducedown-timerelated.

- Enhanced problem solving and performance with company-wide collaboration.

- Can be enabled for mobile, enabling managers with real-time access to vital data for decision making and corrective action.