- Applicable industries: Precision polished bar maker, printer shaft maker, tool maker etc

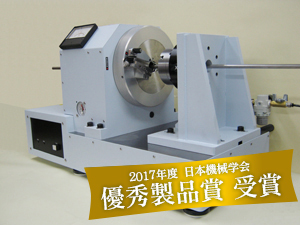

CM-51P

Horizontal roundness measuring machine

World's first! Horizontal roundness measuring machine. It is a measuring machine that does not need to cut the roundness measurement of the long shaft at an arbitrary position. This eliminates wasting the product for measurement.

Circle Master Long Horizontal roundness measuring machine Circle Master Long It is now possible to measure the roundness at an arbitrary position of the long shaft, which was difficult to measure with a conventional table rotation type roundness measuring machine (CM - 50P etc.) .

If measurement can be done without cutting, waste of product and waste of cutting maneuver can be saved.

Small and Medium-sized Manufacturing Advancement Law, "Three, Precision Processing" ② In the advanced targets clearly stipulated in the consideration and guidelines for environmental impact caused by reduction of waste, and it also conforms to this.

When trying to measure the long shaft with a conventional roundness measuring machine, when the shaft is fixed on the table, the shaft runs out unless the table top face and the shaft's right angle are out.

Therefore, problems occur at high position measurement. Traditionally, we cut the vicinity of the part of the shaft where we wanted to measure shortly and measured it, which resulted in waste of the product.

However, this horizontal circularity measuring machine Circle Master Long has made it possible to measure the roundness at an arbitrary position without cutting the shaft.

Place a through hole in the middle of a turntable (hydrostatic air bearing) placed horizontally and pass the long shaft through the hole. Fasten the long shaft at the point you want to measure. The object to be measured is fixed, and the detector (sensor) rotates the circumference of the measurement point and performs measurement. In this way, clamping the part close to the measurement position, the troublesome straightening work is unnecessary.

By installing a support stand at both ends of the measuring machine, the actual length is up to 4 m, but in theory it can be more than 10 m.